Techologies

At the two locations Jena and Bayreuth a wide range of technologies (see below) from synthesis to characterization to processing is available. These technologies are summarized in focus areas and keylabs, which are accessible to all members of the Joint Lab for Polymers Jena-Bayreuth.

Synthesis and upscaling

The Keylab combines the expertise and equipment for the synthesis of functional polymers and their characterization. Reactors ranging from 0.05 – 10 L are available for polymer synthesis from the gram to the kilogram scale.

Contact:

Prof. Dr. Andreas Greiner

Prof. Dr. Ulrich S. Schubert

Bio-based and bio-degradable polymers

The utilization of bio-based resources for the synthesis of polymers becomes more and more important. On the other hand, polymers stay very long in Nature after usage and bio-degradability can be an option to overcome the current waste dilemma.

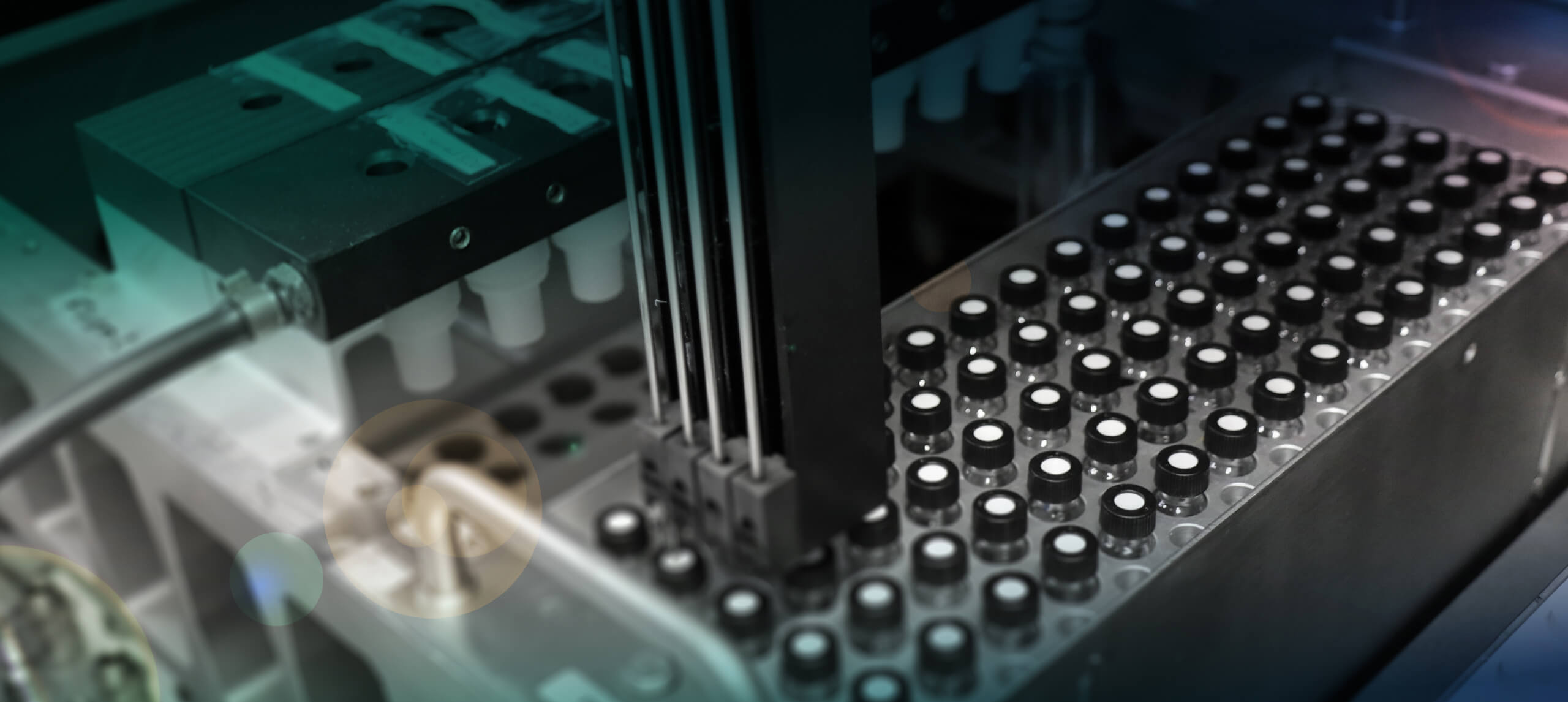

Robot-based chemistry

Robot-based chemistry is performed using automated synthesis able to perform online characterization and purification. A fast screening of a parameter space is possible enabling the generation of large data amounts for, e.g., AI-applications.

Catalysis

Catalysis is a key technology for sustainable polymers and their usage reducing the demand of energy. Special focus in Jena and Bayreuth is the application of catalytic reactions for the defined polymer synthesis; however, polymer-based materials are also utilized as catalysts for hydrogen production and CO2-conversion.

Electron and optical microscopy

Electron and optical microscopy is applied in different research areas to study the structure and morphology of advanced polymer materials, including nano-medicine and (switchable) interfaces. State-of-the-art equipment can be utilized both in Jena and Bayreuth such as cyro-TEM or SEM.

Contact:

PD Dr. Stephanie Höppener

Surface characterization

The investigation of surfaces and interfaces is highly important to study the interaction of polymers. Therefore, different techniques are available to study those methods in detail and to study the structure of surfaces and interactions at interfaces.

Contact:

Prof. Dr. Felix H. Schacher

Solution characterization

The characterization of polymers is essentiell to derive structure-property relationships. For this purpose, solution characterization is performed using state-of-the-art technologies such as analytical ultracentrifugation, size exclusion chromatography and asymmetric flow field-flow fractionation (AF4).

Contact:

Prof. Dr. Ivo Nischang

Scattering

State-of-the-art scattering infrastructure for the characterization of complex structures and in-situ structure formation processes of matter on length scales from 1-250 nm is available at both locations.

Contact:

Prof. Dr. Felix H. Schacher

Prof. Dr. Markus Retsch

Small scale polymer processing

The Keylab Small Scale Polymer Processing is specialized on shaping polymers on a 1 to 100 g scale to fibers, films, and injection molded parts, as well as the incorporation of additives and fillers.

Contact:

Prof. Dr.-Ing Holger Ruckdäschel

Pilot scale polymer processing

Extruders of various types and sizes are available for every process engineering task. The machinery includes single- and twin-screw machines, kneaders, tandem, and laminating lines. This means that our experienced staff can cover a wide range of processing and compounding tasks from laboratory to pilot plant scale.

Contact:

Prof. Dr.-Ing Holger Ruckdäschel

Thermoset and composite processing

Due to their reactive processing, thermoset materials require specialized manufacturing technology. We have a wide range of modern equipment at our disposal to handle a variety of thermoset moulding compounds and materials safely and efficiently. These include epoxy resins, polyurethanes, polyesters, acrylates, and many more. Furthermore, intelligent polymer networks can be processed as well.

Contact:

Prof. Dr.-Ing Holger Ruckdäschel

Prof. Dr. Ulrich S. Schubert

Foam processing

The production of polymer foams are possible using a variety of processes for the production of autoclave, particle, extrusion, and injection moulded foams. Foams of various structures can be produced using the right production parameters and targeted material modification. The spectrum ranges from standard plastics to high-temperature thermoplastics.

Contact:

Prof. Dr.-Ing Holger Ruckdäschel

Functional particles

Particles of nano- and micrometer size are highly interesting candidates in catalysis and biomedical applications. The targeted synthesis using different approaches including microfluidics feature the opportunity to design tailor-made particular systems.

Contact:

Dr. Stephanie Schubert

Gene and drug delivery

The delivery of drugs and genes within the human offers a great potential for targeted medicine. For this purpose, polymers can help to delivery drugs to the right place reducing unwanted side effect leading to a more efficient medicine.

Contact:

Dr. Anja Träger

Prof. Dr. Michael Bauer

Intelligent polymers

Stimuli-responsive polymers can be triggered by a certain external stimulus changing their properties. This behavior can be utilized to design functional and switchable materials, including shape-memory, self-healing or recyclable polymers.

Contact:

Dr. Martin D. Hager

Energy storage and conversion

The storage of energy and its conversion is a great challenge currently enabling a greener production of electric energy. Therefore, new battery systems and solar cells are required and are developed at both locations.

Contact:

Prof. Dr. Ulrich S. Schubert

Apl.-Prof. Dr. Seema Agarwal

Prof. Dr. Yan Lu

Theory and simulation

Simulations using the power of present-day supercomputers have become an indispensable tool in all areas of modern science. Using a variety of computational methods, we investigate macromolecular and other organic structures on different length and time scales.

Contact:

Prof. Dr. Stefanie Gräfe

Artificial intelligence and machine-learning

The application of AI and ML is rapidly growing and first approaches in polymer science are also described. Jena and Bayreuth are at the forefront of AI-based polymer research developing new methods for different applications.

Contact:

Jun.-Prof. Dr. Christopher Künneth

Prof. Dr. Ulrich S. Schubert

Dr. Kevin Jablonka